- Home

- Cruise Mesh Cap - White Front

Cruise Mesh Cap - White Front

- We strive to minimize production lead times for custom printed product orders, however during periods of high demand, these may be extended.

- Please contact your Account Manager if you require an earlier despatch date than the current standard lead time and we will do our best to accommodate where possible.

- The standard lead times are applied to orders approved prior to 5:30 pm (NZT). For orders approved after this time please allow +1 working day.

- Orders for large quantities (5th and 6th column) may also require additional production time, please discuss any urgent orders for these quantities with your Account Manager.

| Process | Standard Lead Time (working days) |

|---|---|

| ColourFlex Transfer/Faux Embroidery | 4 Days |

| ColourFlex Transfer/Faux Embroidery - Headwear | 4 Days |

| ColourFlex Transfer/Faux Embroidery - Umbrellas | 4 Days |

| Custom Packaging - Digital Print | 4 Days |

| Debossing | Hot Stamping | 3 Days |

| Digital Label | 3 Days add 1 day for assembly items |

| Direct Digital | 3 Days |

| Direct Digital - Notebooks | 3 Days |

| Direct Digital - Pens | 3 Days |

| Embroidery (up to 10k stitches) | 4 Days |

| Foil Printing | 3 Days |

| Kitting | The process with the longest lead time +2 days |

| Laser Engraving | 3 Days |

| Laser Engraving - Drinkware | 4 Days |

| Laser Engraving - Pens | 3 Days |

| Multi-Process | The process with the longest lead time +1 day |

| Pad Print | 4 Days |

| Pad Print - Multi Colour | 4 Days |

| Pad Print - Multi Colour - Pens | 3 Days |

| Pad Print- Pens | 3 Days |

| Resin Label | 3 Days add 1 day for assembly items |

| Rotary Digital | 5 Days |

| Screen Print - Bags/Textiles | 4 Days |

| Screen Print - Bottles | 4 Days |

| Screen Print - Flat Bed | 3 Days |

| Screen Print - Mugs/Cups | 3 Days + 1 for assembly |

| Screen Print - Notebooks | 3 Days |

| Screen Print - Pens | 3 Days |

| Screen Print - Umbrellas | 3 Days |

| Silicone Debossing | 3 Days + 1 for assembly items |

| Silicone Digital Print | 3 Days + 1 day for assembly items |

| Sublimation - Flat | 3 Days + 1 day for assembly items |

| Sublimation - Mugs | 3 Days |

| Sublimation - Umbrellas | 3 Days |

| x Melbourne Production | 6 Days |

Proofs

We will send you a digital artwork proof before printing commences. Check the proof carefully and if the correct sign or electronically approve it and return the signed or electronically approved proof to us. If in our opinion the print colours or artwork are not appropriate for the product ordered or will only give average results we will make a recommendation on the proof. We do not accept claims arising from issues we have drawn attention to in our recommendations. No printing will proceed without a signed proof. We take no liability for errors or omissions once a proof is signed so please check proofs carefully.

Sending Orders and Artwork

Email your order with the artwork attached to info@bizpromo.co.nz, ensure the job name and order number or invoice(Quote) number are in the subject or invoice(Quote). Always remember to send your artwork in one of our useable formats. More information is available in the Artwork Information section below. It is your responsibility to ensure you have approval from the owner of the artwork to use it.

Required Artwork Format - Vector

A vector graphic is an ideal format to supply artwork as the majority of decorating processes including pad printing, screen printing and laser engraving can only use vector artwork. Vector artwork can also be easily converted into raster artwork if required. Artwork in this format is saved as mathematical equations and can easily be edited and resized without compromising the image quality.

Vector artwork can be supplied in the following file types:

-

EPS – Encapsulated PostScript

-

CDR – Corel Draw

-

AI – Adobe Illustrator

-

PDF – Portable Document Format (ensure artwork is converted to curves / paths to avoid font conflicts) - Important note: Please note that saving as PDF or above format from Bitmap is not a vector artwork. The PDF should be saved from the original vector.

Please refer to the table below for comparison.

What are vector and bitmap images, and how are they different?

Vector vs. Bitmap Images - Comparison

What if you don’t have any of these formats above?

- We recommend that you contact the person who created your logo or artwork. Normally, the designer can supply it in a vector format if they create your logo with one of the programs above.

- If you don’t have any of these formats above and don’t have a designer, we can redraw your logo for $35+gst per logo. Please note that if the artwork is too complicated, it may incur an extra cost.

For the full information, please click the link below.

What are vector and bitmap images, and how are they different?

Artwork Ownership

All artwork, film, plates and screens created by Bizpromo in the production of an order remain the property of Bizpromo Ltd.

Product Colours

The product colours illustrated in our catalogue and website are matched as closely as the printing process will allow. Actual product colours may vary and they can also vary from shipment to shipment and this is beyond our control. Always ask to see a sample to verify the product colour is suitable for your requirements as we do not accept returns due to minor colour variations.

PMS Colours

The Pantone Matching System (PMS) was designed for mixing and controlling colours within the offset printing industry and the colour fidelity of this system is achieved using offset printing inks printed on coated and matt white paper stock. All other printing processes including digital printing have adopted the PMS system as a colour reference guide only for colour matching. It is important to remember that the inks used in such printing processes cannot be mixed according to the PMS recipes so PMS matches on promotional products can vary from almost perfect in some processes to only approximate in others. The colour of the product chosen is also a big factor in our ability to match PMS colours. Please do not hesitate to ask for more information about PMS colours if you have any concern as to whether the printing process can deliver the level of accuracy you require on the products you order. For pad and screen printing, close PMS colour matches are best achieved on white products. Reasonably close matches can also be achieved on frosted clear and silver surfaces but as the colour of the product gets darker the ability to match PMS colours diminishes. Full colour digital printing processes can only achieve approximate PMS colour matches at best. It is very important to be aware of this limitation as it is unavoidable and we do not accept returns based on digitally generated colours not matching PMS colours.

Product Suitability

Please ask to see an actual sample of the product you wish to order to ascertain its suitability for your requirements. We do not accept returns of products deemed not to be suitable for the desired purpose for any reason after they are decorated.

Pre-Production Samples

We will warn you about printing limitations including the ability to match PMS colours on your proof. If you have any concerns that the finished product may not meet the standards you require we strongly recommend requesting a pre-production sample. The cost of pre-production samples is determined by the cost of the applicable setup charges plus the cost of the product. Once the pre-production sample is approved, normal setup charges apply to the production run.

How the process works for custom printed promotional products.

Please advise the details below for fast and accurate service.

- Product name and SKU number (at the bottom of the product description).

- Product colour and order quantity.

- Supply logo or artwork in a vector format.

- Supply PMS Colour number of logo from the solid coated Pantone range; PMS (PANTONE Solid Coated Code) chart or link will be sent to you if you don’t know. What is PMS Color?

- Supply company details and delivery address.

- If the order is required to be delivered on a specific date, please inform us of the date.

How to place printing orders / Orders and Quantities

| Order proceeding steps via email | Order proceeding steps via website |

|

1. Quotation will be sent to you as requested. Please note that it is important that you let us know if you don’t receive the notification of step 3, 6 and 8. |

1. Required to supply an artwork in a vector format. Please note that it is important that you let us know if you don’t receive the notification of step 2, 4 and 6. |

Related Products

Magnetic Note Pad - Home Sweet Home

$1.10

Magnetic Note Pad - Home Sweet Home

$1.10

Description

An ideal way to keep your name in front of customers - just add your business card! Perfect for trade shows, sales meetings, prospecting, or client visits, these Magnetic Business Card Note Pads turn any business card into a practical and memorable gift. Ready within 48 hours or less, they're a fast and effective promotional solution...

Magnetic Note Pad - Plain

$1.10

Magnetic Note Pad - Plain

$1.10

Description

An ideal way to keep your name in front of customers - just add your business card!Perfect for trade shows, sales meetings, prospecting, or client visits, these Magnetic Business Card Note Pads turn any business card into a practical and memorable gift. Ready within 48 hours or less, they're a fast and effective promotional solution....

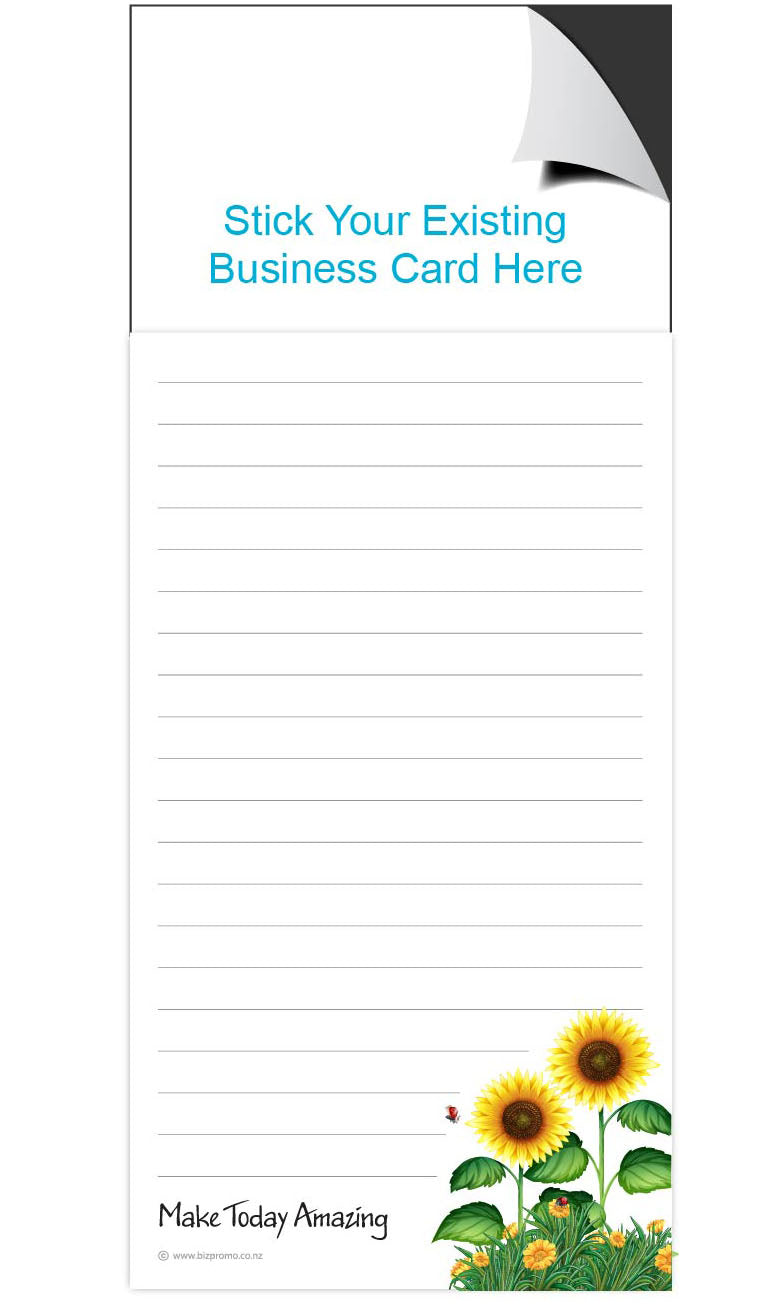

Magnetic Note Pad - Make Today Amazing

$1.10

Magnetic Note Pad - Make Today Amazing

$1.10

Description

An ideal way to keep your name in front of customers - just add your business card! Perfect for trade shows, sales meetings, prospecting, or client visits, these Magnetic Business Card Note Pads turn any business card into a practical and memorable gift. Ready within 48 hours or less, they're a fast and effective promotional solution...

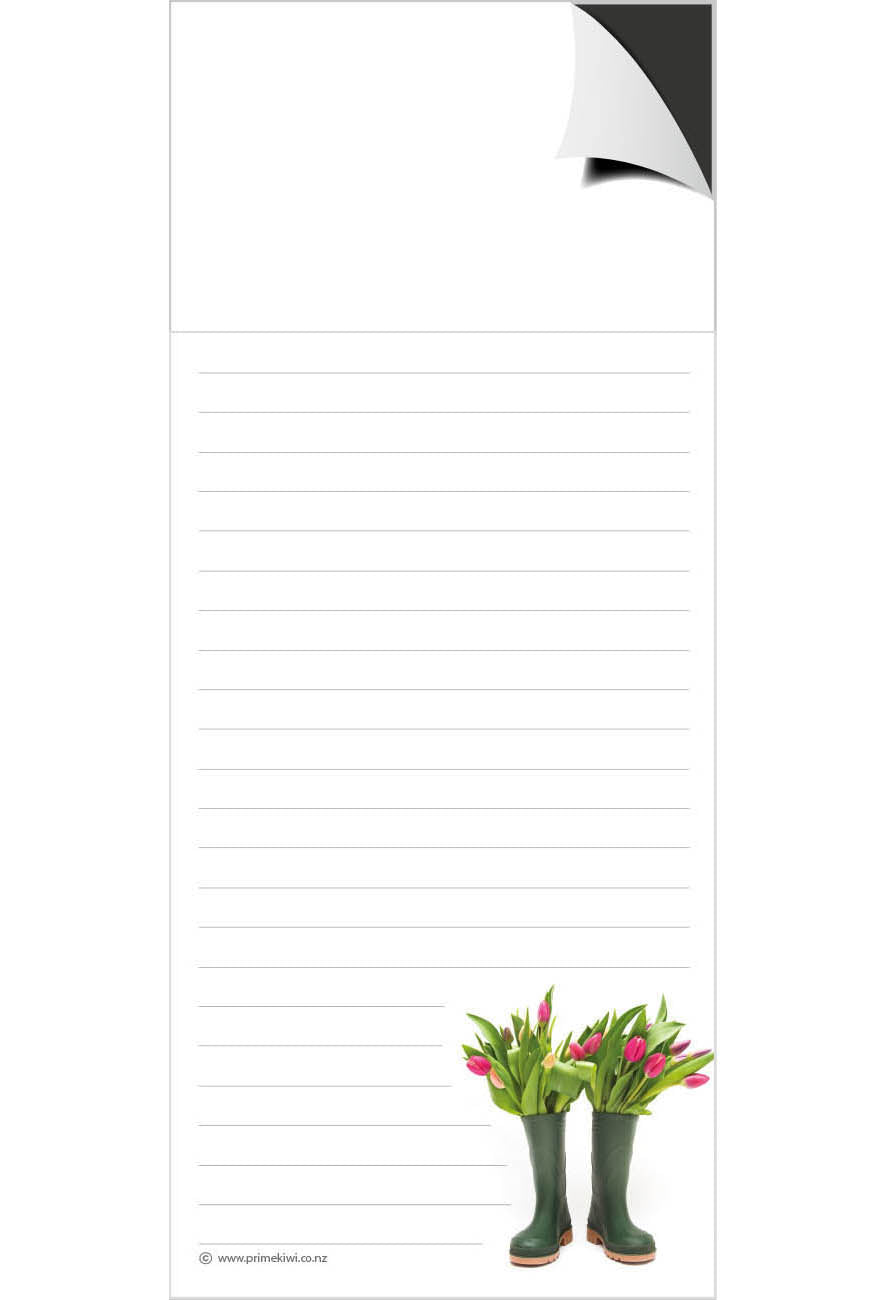

Magnetic Note Pad - Gumboots

$1.10

Magnetic Note Pad - Gumboots

$1.10

Description

An ideal way to keep your name in front of customers - just add your business card! Perfect for trade shows, sales meetings, prospecting, or client visits, these Magnetic Business Card Note Pads turn any business card into a practical and memorable gift. Ready within 48 hours or less, they're a fast and effective promotional solution...

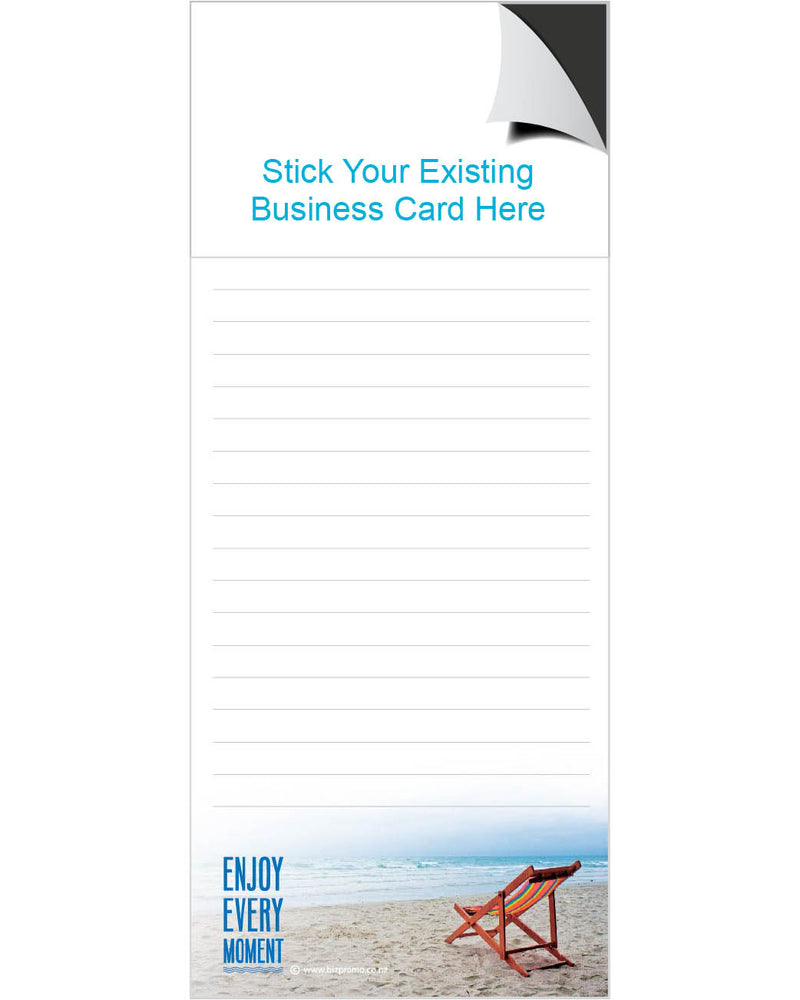

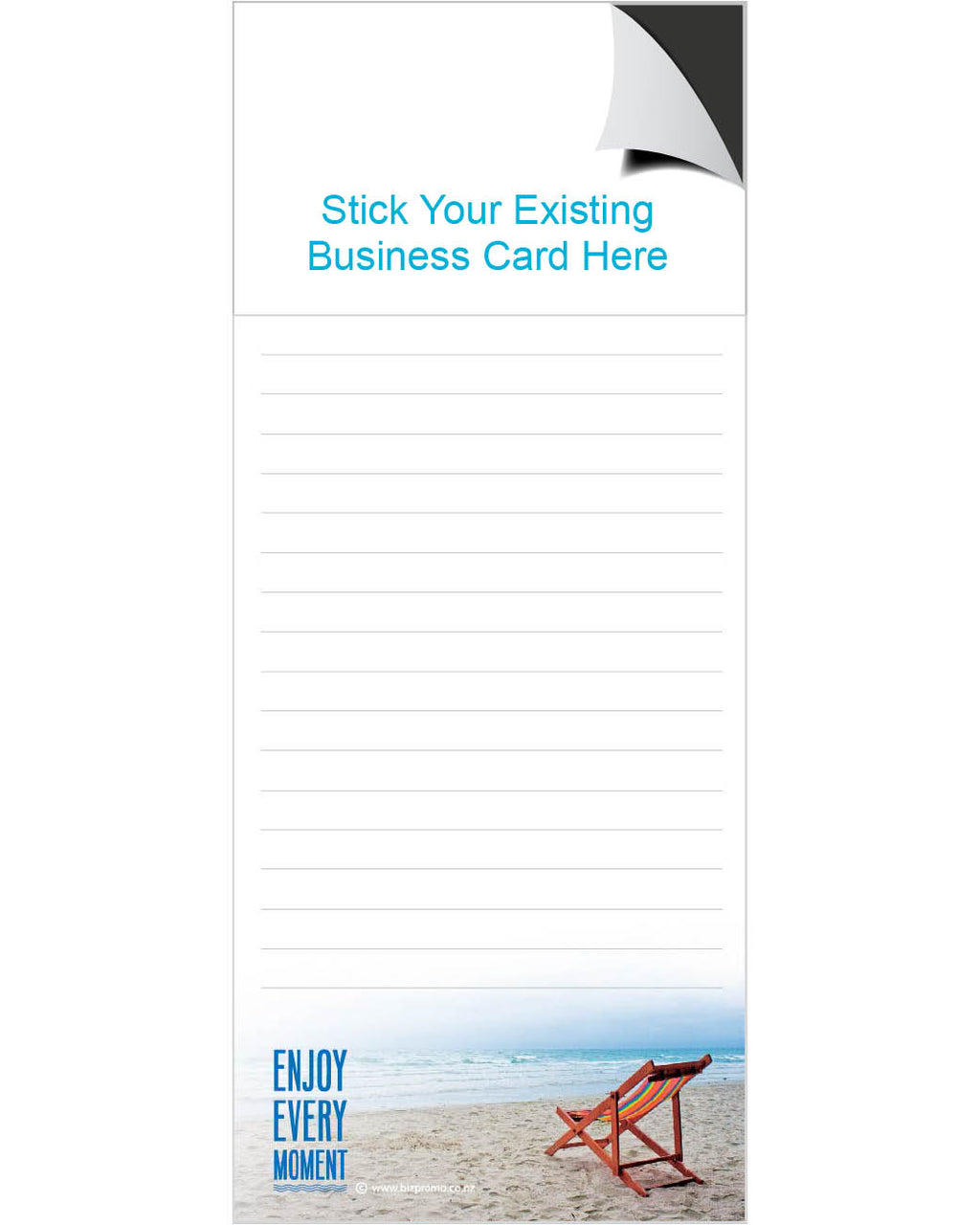

Magnetic Note Pad - Enjoy Every Moment

$1.10

Magnetic Note Pad - Enjoy Every Moment

$1.10

Description

An ideal way to keep your name in front of customers - just add your business card! Perfect for trade shows, sales meetings, prospecting, or client visits, these Magnetic Business Card Note Pads turn any business card into a practical and memorable gift. Ready within 48 hours or less, they're a fast and effective promotional solution...

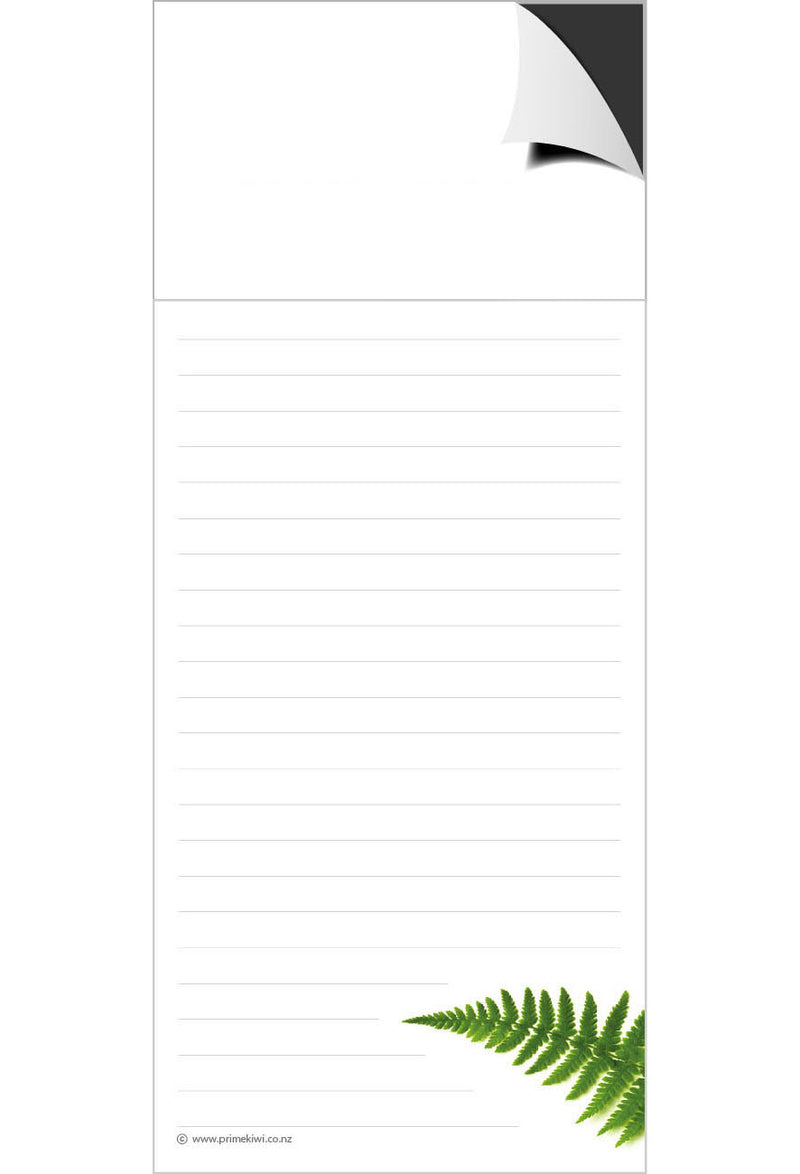

Magnetic Note Pad - Silver Fern

$1.10

Magnetic Note Pad - Silver Fern

$1.10

Description

An ideal way to keep your name in front of customers - just add your business card! Perfect for trade shows, sales meetings, prospecting, or client visits, these Magnetic Business Card Note Pads turn any business card into a practical and memorable gift. Ready within 48 hours or less, they're a fast and effective promotional solution...

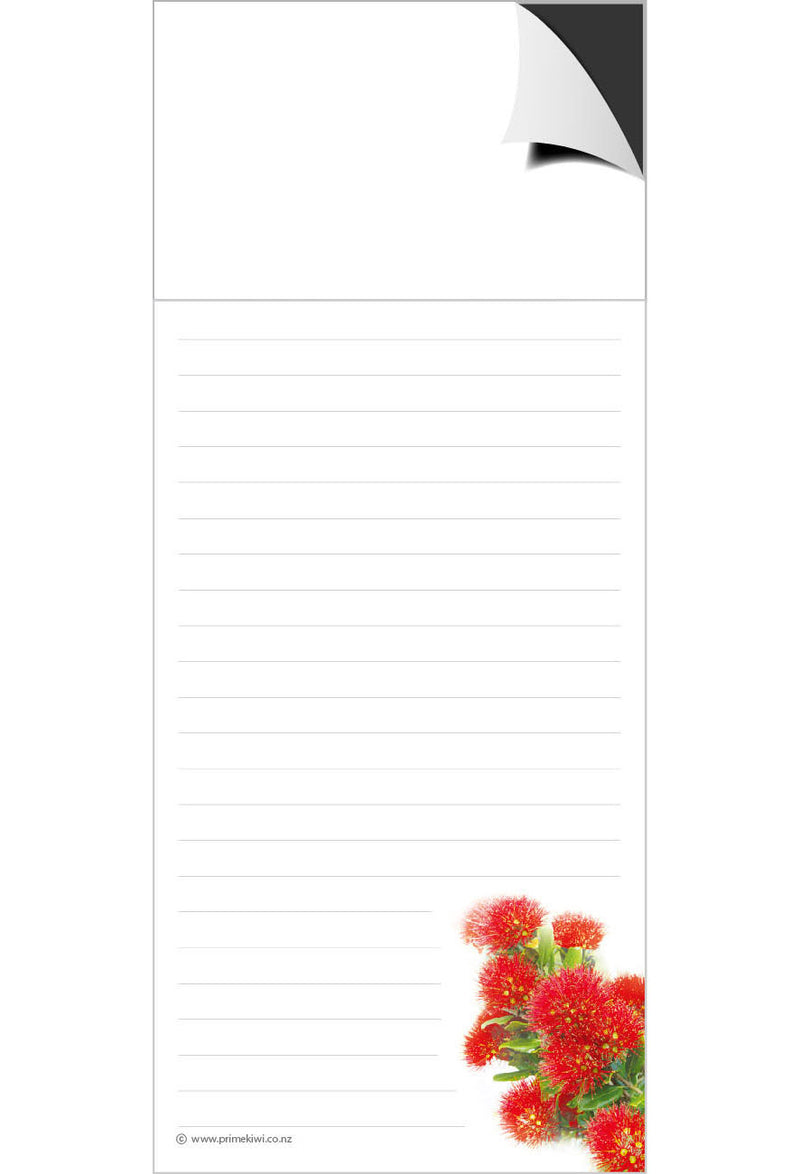

Magnetic Note Pad - Pohutukawa

$1.10

Magnetic Note Pad - Pohutukawa

$1.10

Description

An ideal way to keep your name in front of customers - just add your business card! Perfect for trade shows, sales meetings, prospecting, or client visits, these Magnetic Business Card Note Pads turn any business card into a practical and memorable gift. Ready within 48 hours or less, they're a fast and effective promotional solution...

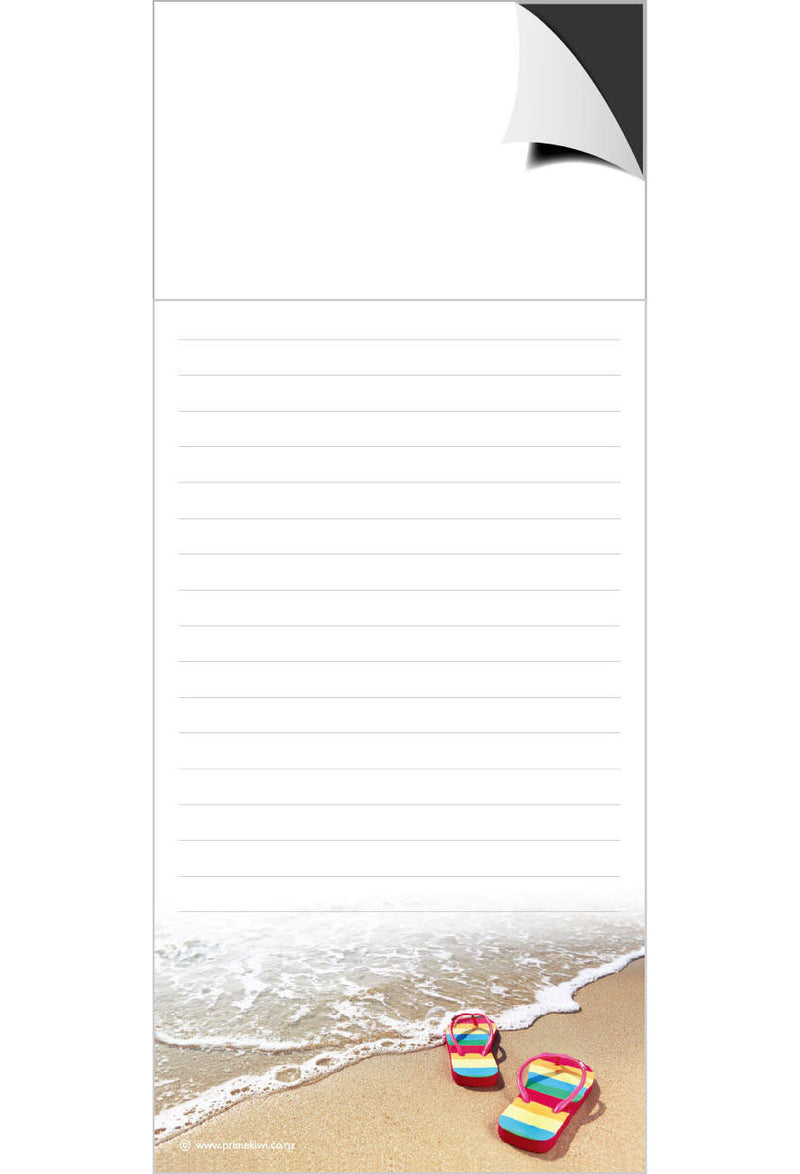

Magnetic Note Pad - Jandals

$1.10

Magnetic Note Pad - Jandals

$1.10

Description

An ideal way to keep your name in front of customers - just add your business card! Perfect for trade shows, sales meetings, prospecting, or client visits, these Magnetic Business Card Note Pads turn any business card into a practical and memorable gift. Ready within 48 hours or less, they're a fast and effective promotional solution...

2026 Magnetic Calendar - Home Sweet Home (12 Months)

$1.25

2026 Magnetic Calendar - Home Sweet Home (12 Months)

$1.25

Description

Magnetic Calendars - Ready-to-Use & CustomisableMagnetic calendars are one of the best ways to keep your brand visible year-round. We supply them unbranded and ex-stock within 48 hours, allowing you to add your business cards for a simple and effective promotional tool. Designed to stick securely to fridges, filing cabinets, or o...

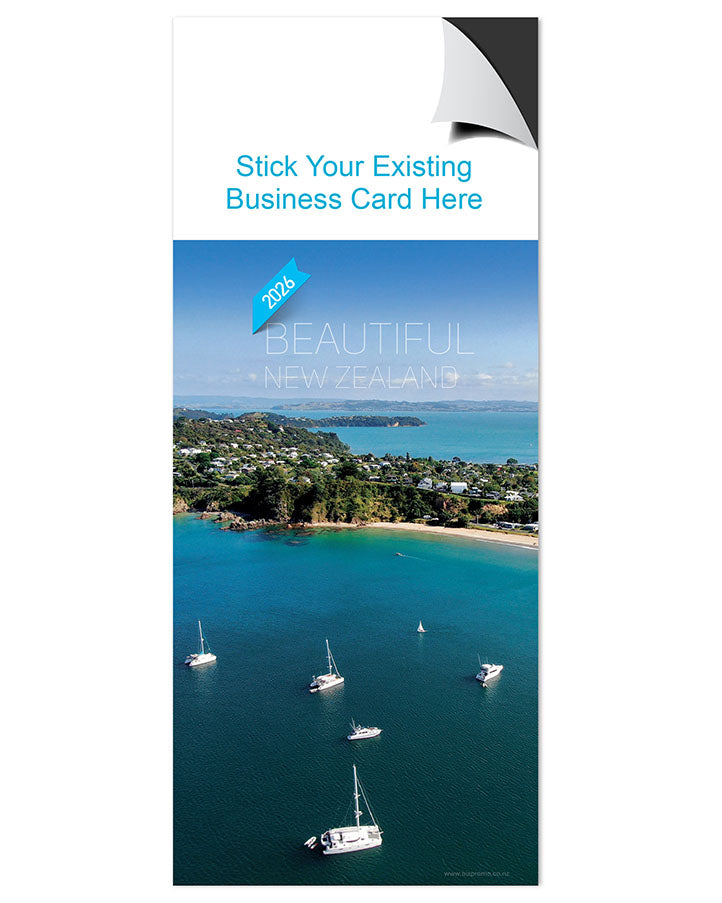

2026 Magnetic Calendar - Beautiful New Zealand (12 Months)

$1.25

2026 Magnetic Calendar - Beautiful New Zealand (12 Months)

$1.25

Description

Magnetic Calendars - Ready-to-Use & CustomisableMagnetic calendars are one of the best ways to keep your brand visible year-round.We supply them unbranded and ex-stock within 48 hours, allowing you to add your business cards for a simple and effective promotional tool. Designed to stick securely to fridges, filing cabinets, or ot...

2026 Magnetic Calendar - New Zealand Landmarks (12 Months)

$1.25

2026 Magnetic Calendar - New Zealand Landmarks (12 Months)

$1.25

Description

Magnetic Calendars - Ready-to-Use & CustomisableMagnetic calendars are one of the best ways to keep your brand visible year-round. We supply them unbranded and ex-stock within 48 hours, allowing you to add your business cards for a simple and effective promotional tool. Designed to stick securely to fridges, filing cabinets, or o...

2026 Magnetic Calendar - Remarkable New Zealand (12 Months)

$1.25

2026 Magnetic Calendar - Remarkable New Zealand (12 Months)

$1.25

Description

Magnetic Calendars - Ready-to-Use & CustomisableMagnetic calendars are one of the best ways to keep your brand visible year-round.We supply them unbranded and ex-stock within 48 hours, allowing you to add your business cards for a simple and effective promotional tool. Designed to stick securely to fridges, filing cabinets, or o...